TPM: The philosophy and Evolution phases

Philosophy

TPM aims at using equipments to its maximum and aids in reducing life cycle costs (LCC). In other words going all out to eliminate the Losses (Waste) cased by the equipment.

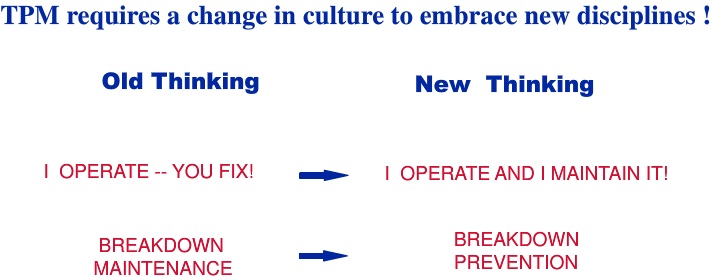

TPM improves work activities that deal with equipment Set-up, Operaing parameters, Maintenance, Tear down, Repairs and Breakdowns etc.

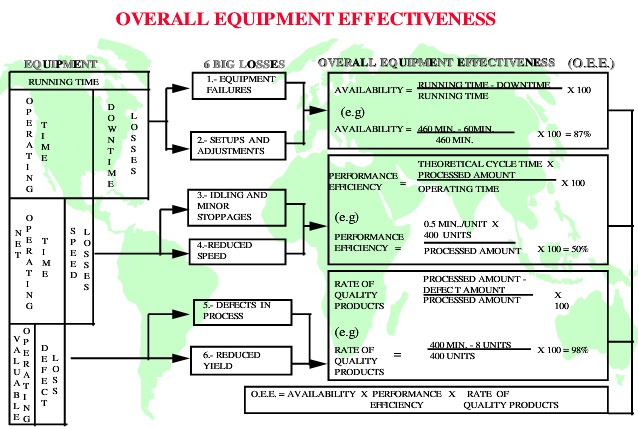

It specifically aims at the complete elimination of the "six major losses" while strving for a goal of zero unscheduled downtime, Zero defect and Zero accident.

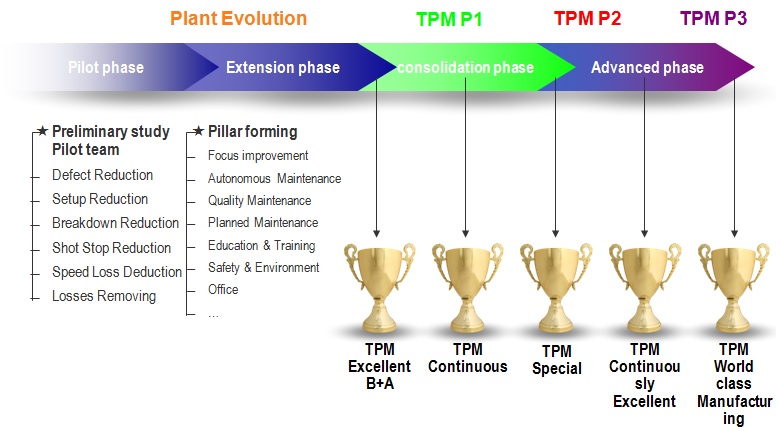

Pilot phase

Pilot phase is the start of the journey, it lasts 6 months normally.

Pilot teams are formed to attack some of the critical problems of the company.

The company starts the process of driving the system from targets.

Target of pilot teams

Start people involvement.

Practise method on how to improve.

Obtain significant results on important issues for the company (Minimum target 50%).

At the end of the pilots, many potential TPM leaders are trained for the future teams.

3 Key words

Involvement

Method

Result

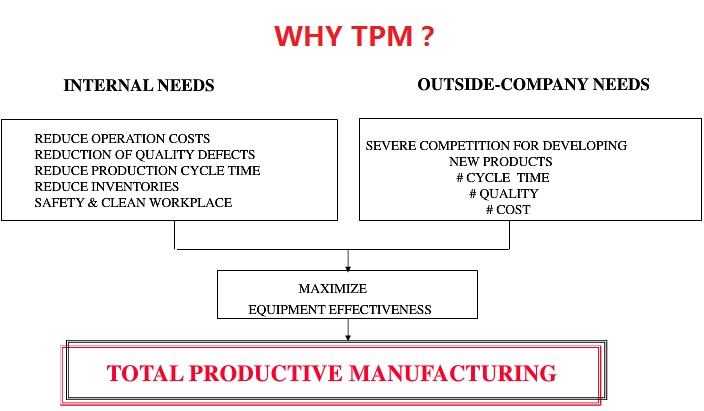

Why does the enterprise need TPM?

Through TPM, we can

- Maximize equipment effectiveness.

- Develop a system of productive maintenance that plan, design, use or maintain equipment in implementing TPM.

- Actively involve manufacturing specialists.

- Reduce waste or losses.

- Increase utilization of employee knowledge and skills.

- Improve product quality and consistency.

With the definite target being as the followings,

0 unplanned downtime

0 speed losses including asset idle time

0 defects

0 accidents

Minimum life cycle cost of asset.

And the general target of TPM is OEE which is the abbreviation of total equipment effectiveness.